Hydrogen is colourless but, in specialist jargon, colours are attributed to it to distinguish the methods used for extraction and their environmental impact.

Grey hydrogen is produced from fossil energy sources through so-called steam reforming. The hydrogen is obtained from natural gas or from the gasification of coal via a process of thermochemical conversion that also produces CO₂. This method is the most harmful for the environment.

Blue hydrogen is obtained using a process in some ways similar to that used for grey hydrogen: it is extracted from fossil sources through pyrolysis. This method too produces CO₂ but in this case it is captured and stored underground or used as a raw material in conversion processes. It is a more environmentally friendly process thanks to the absence of climate-damaging emissions.

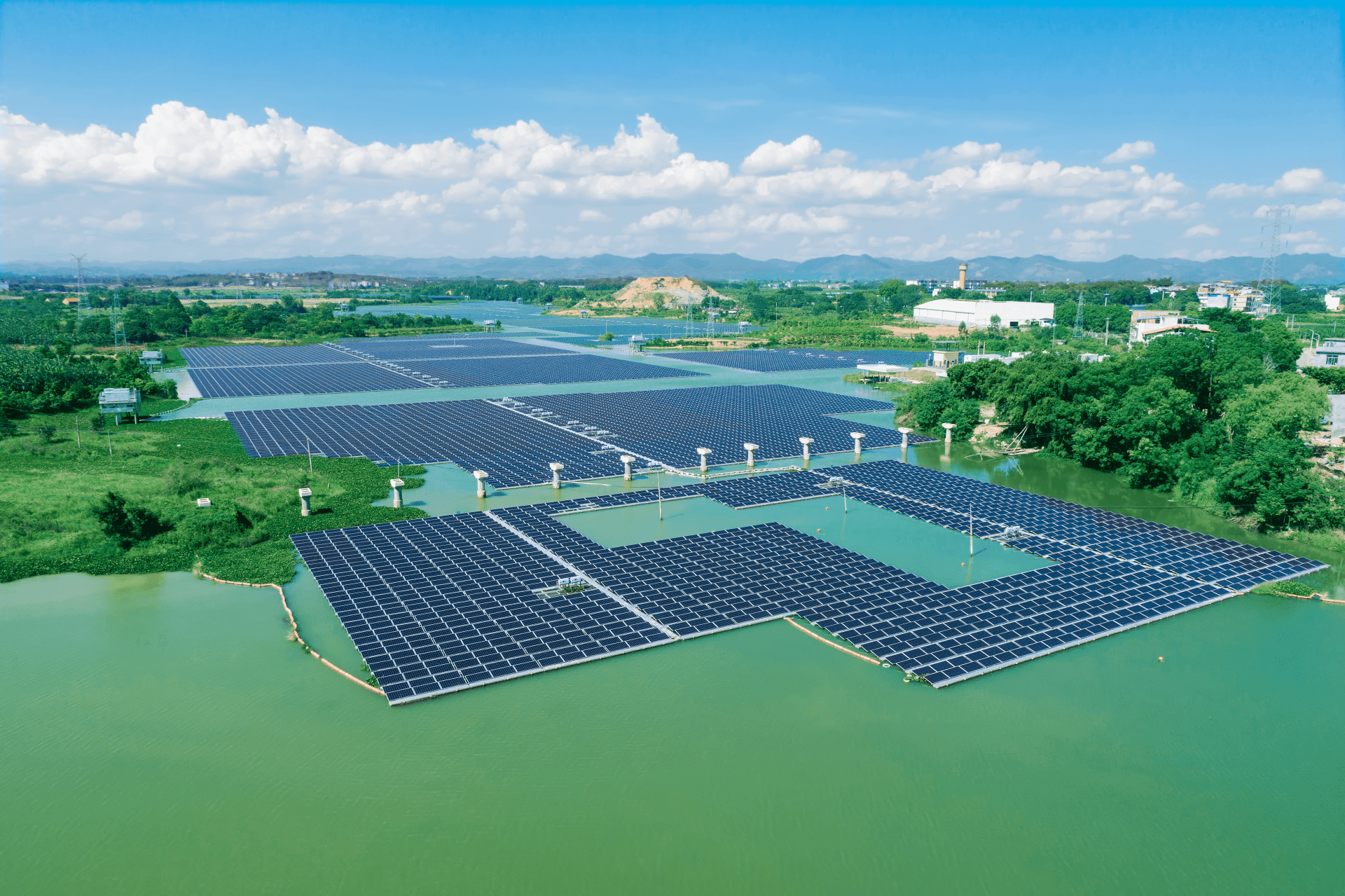

Green hydrogen is produced by a process called high-temperature electrolysis: the water molecules (H₂O) receive energy produced from renewable sources (such as photovoltaics or wind), the bonds are broken and the result is hydrogen and oxygen. It is worth noting that the bases for the process of electrolysis are to be found in the battery that Alessandro Volta invented in 1779. The hydrogen and oxygen present in water were first separated by the scientists Nicholson and Carlisle.